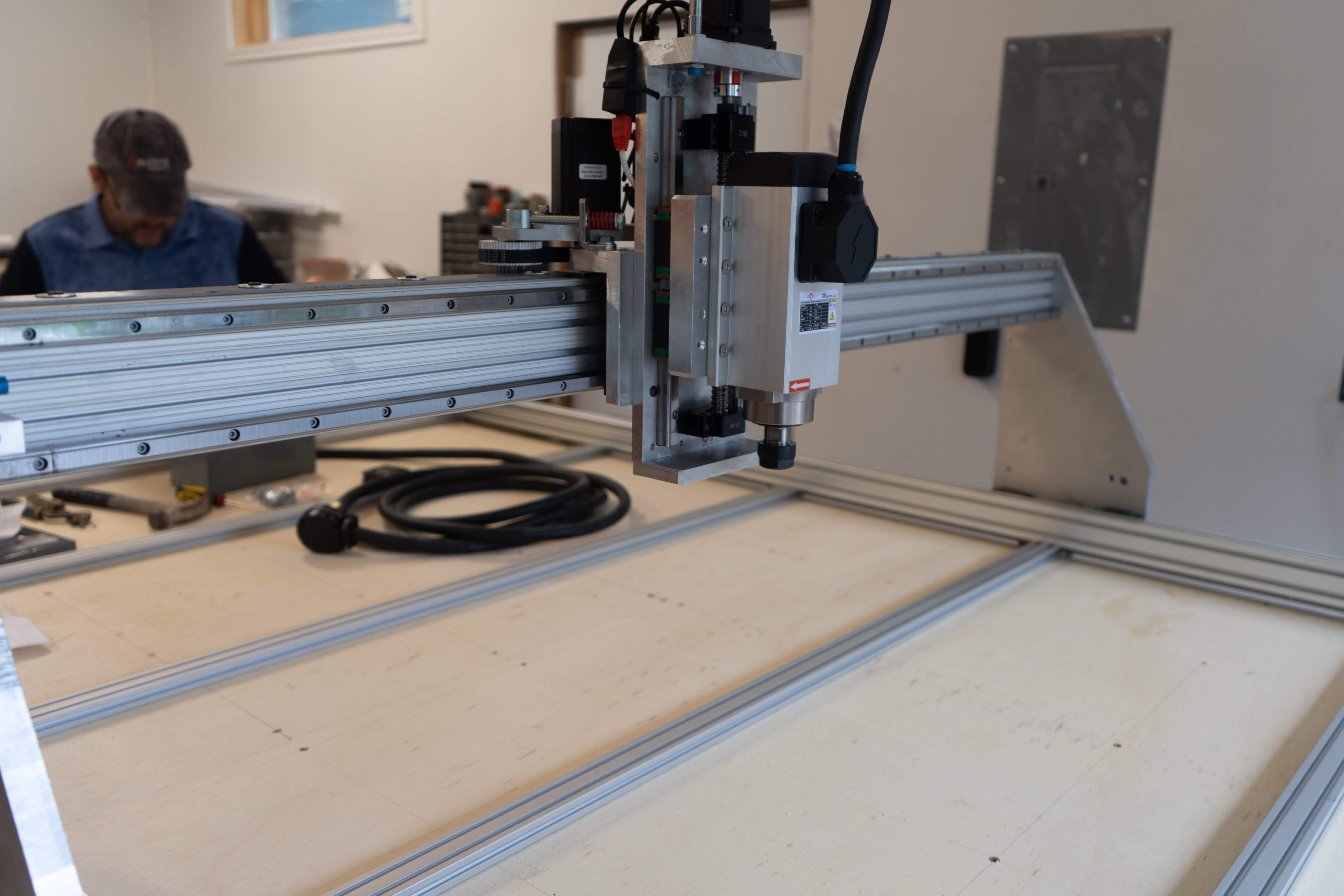

Building the OpenBuilds OX CNC: A Hybrid Kit Approach

A hybrid approach combining V-slot extrusion with 3D printed parts to build a capable benchtop CNC router

From 2014 to 2020, I documented building increasingly capable CNC machines, starting with a hybrid kit approach and eventually achieving precision manufacturing at production scale. This series chronicles the tool-building-tools philosophy: each machine enabled construction of more capable machines.

The journey demonstrates how bootstrapping manufacturing capability creates expanding possibilities: the OX router enabled precision machining for the G0704 conversion, which then machined all components for the large-format gantry router.

CNC development paralleled 3D printing evolution. The RepRap Mendel printed mounting brackets and custom parts for the OX. The OX then machined precision components for upgraded Mendel designs and for better tooling. Each machine ecosystem enabled the other to evolve—a practical demonstration of collaborative tool development where manufacturing capability expanded in both domains simultaneously.

See the RepRap Journey for the complete story of that parallel progression.

Editor’s Note (2025): These projects span 6 years of workshop tool evolution. Modern CNC machines are increasingly accessible and capable, with commercial systems offering performance that once required extensive custom engineering. However, the fundamental principles remain the same: proper design, precision alignment, quality components, and rigorous calibration. The tool-building approach continues to influence hobby machining and maker communities: using available equipment to construct increasingly capable systems.

A hybrid approach combining V-slot extrusion with 3D printed parts to build a capable benchtop CNC router

Converting a manual Grizzly mill to precision three-axis CNC using the OX router to bootstrap the machining

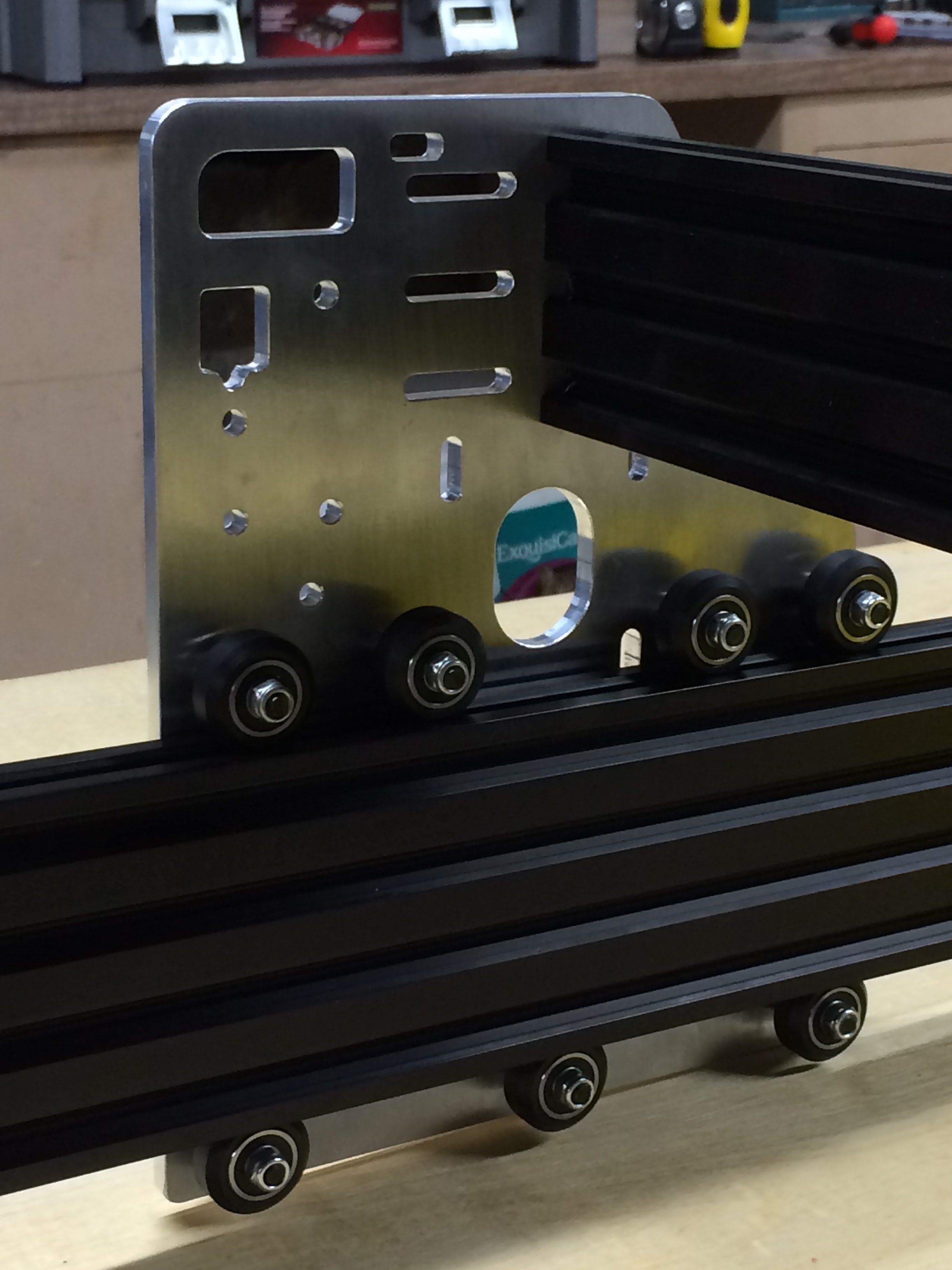

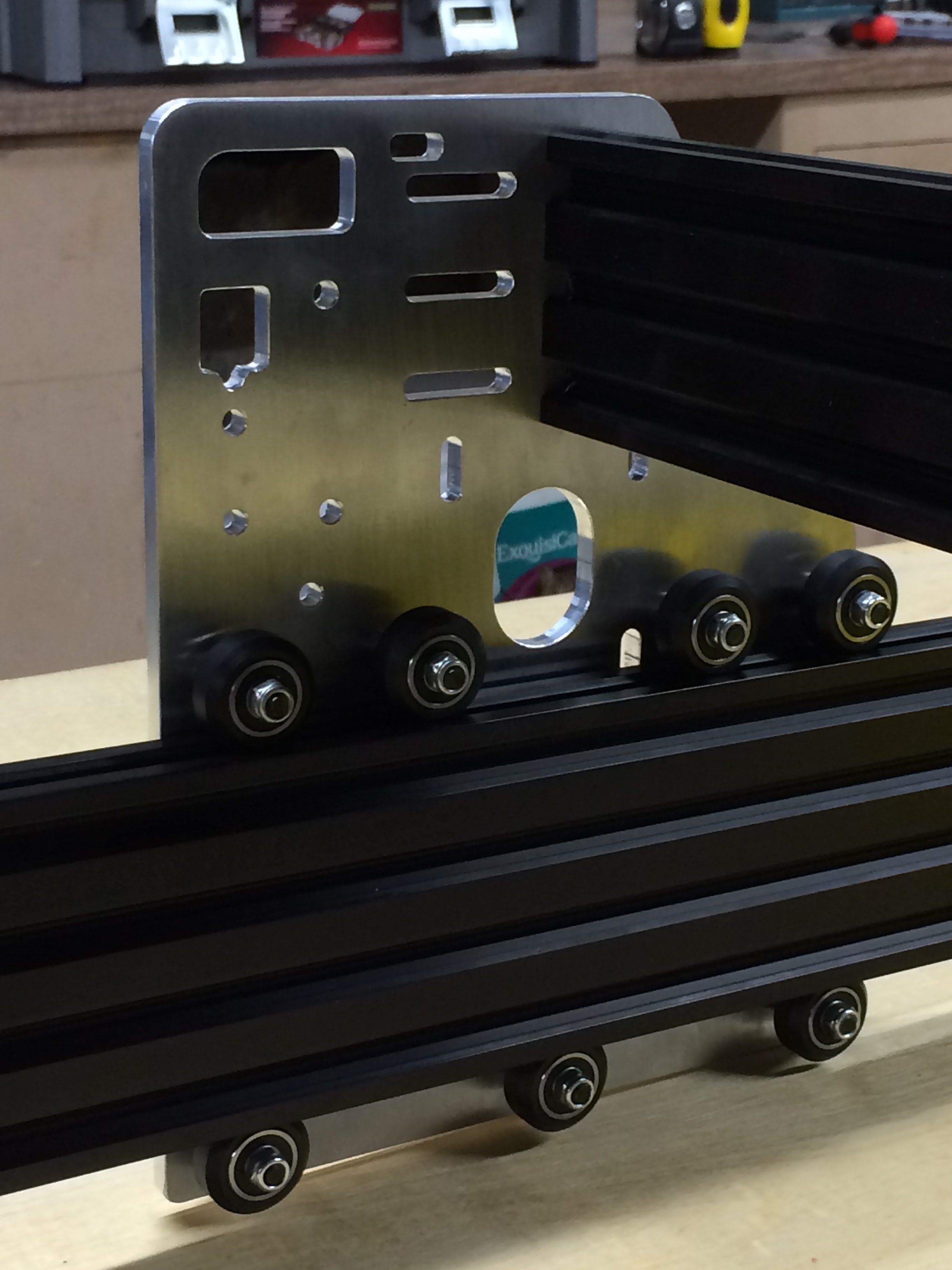

A 5×10ft production-scale CNC router with rack-and-pinion drives and custom-machined aluminum gantry plates