After years of working with RepRap 3D printers, I wanted serious CNC milling capability. The OpenBuilds OX offered the perfect middle ground between buying a complete kit and building from scratch. The design used commercially available V-slot extrusion and machined gantry plates, combined with 3D printed brackets and hand-assembled electronics. This hybrid approach let me use my existing skills while avoiding the McWire’s from-scratch struggles.

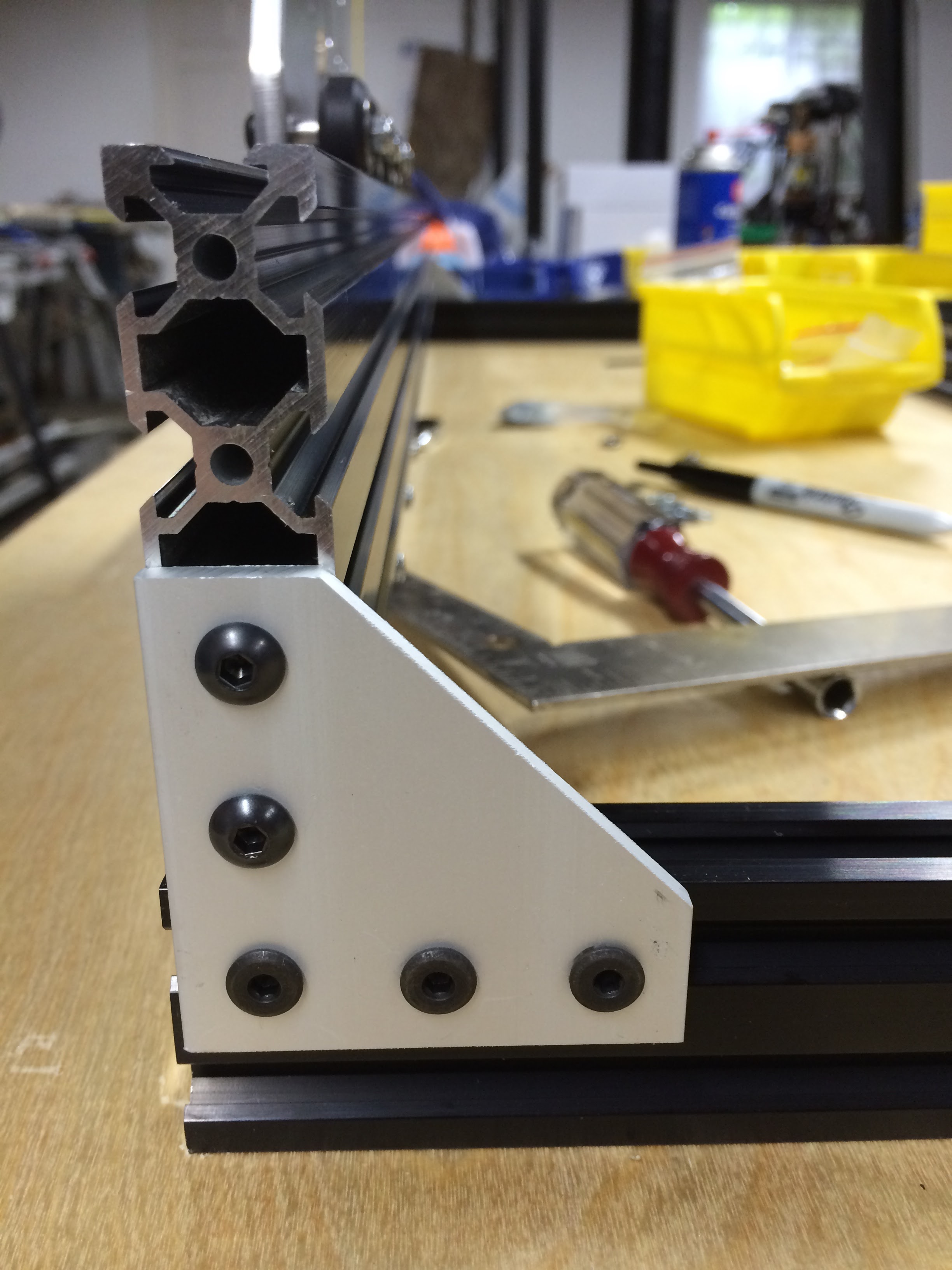

The OX appealed to me because OpenBuilds’ V-slot extrusion eliminates separate linear rails - the V-groove profile guides V-wheels directly, creating simple and rigid linear motion. The design was modular and scalable, and critical components like gantry plates were available off the shelf. This solved the chicken-and-egg problem of needing a mill to make mill parts.

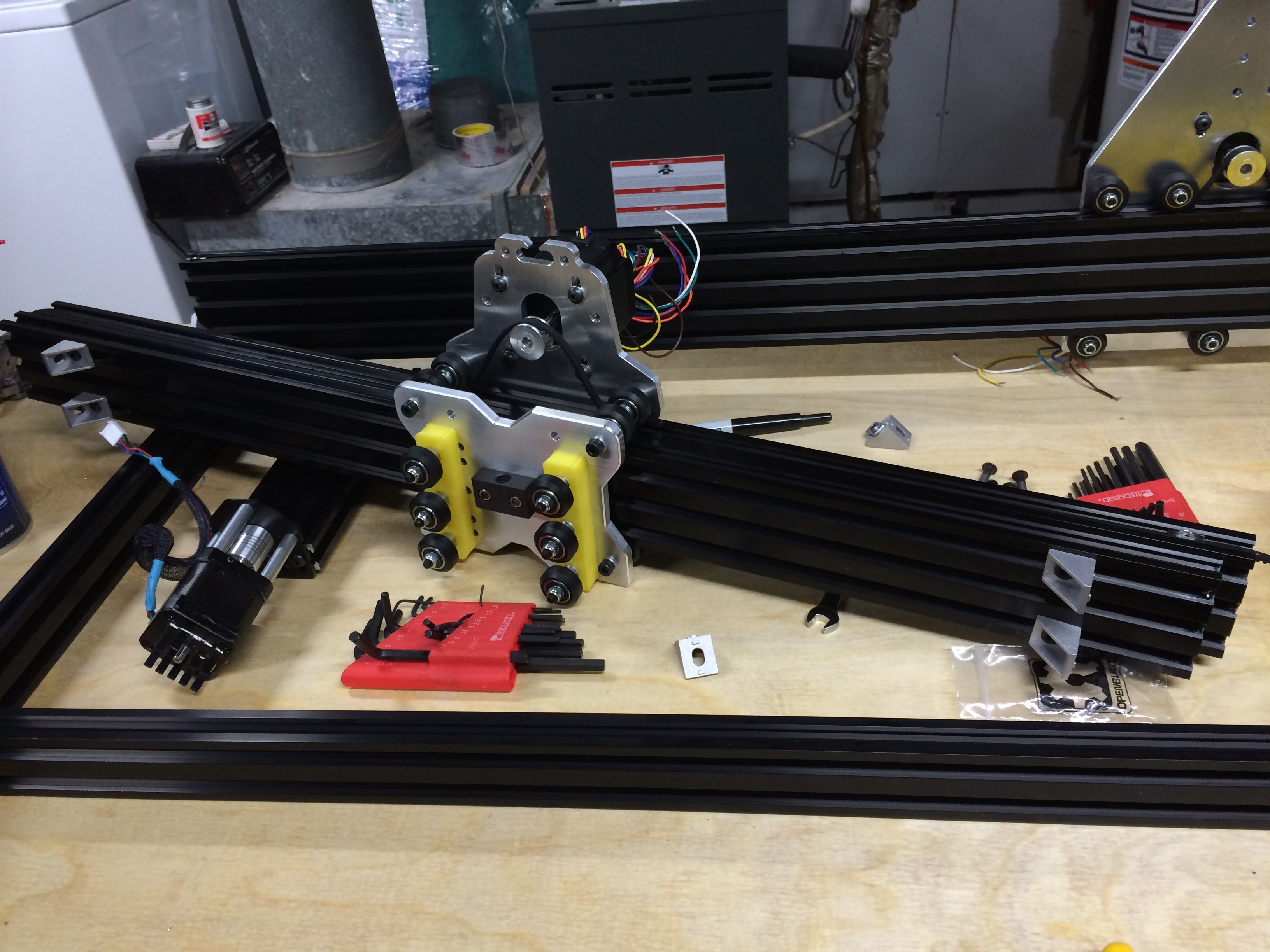

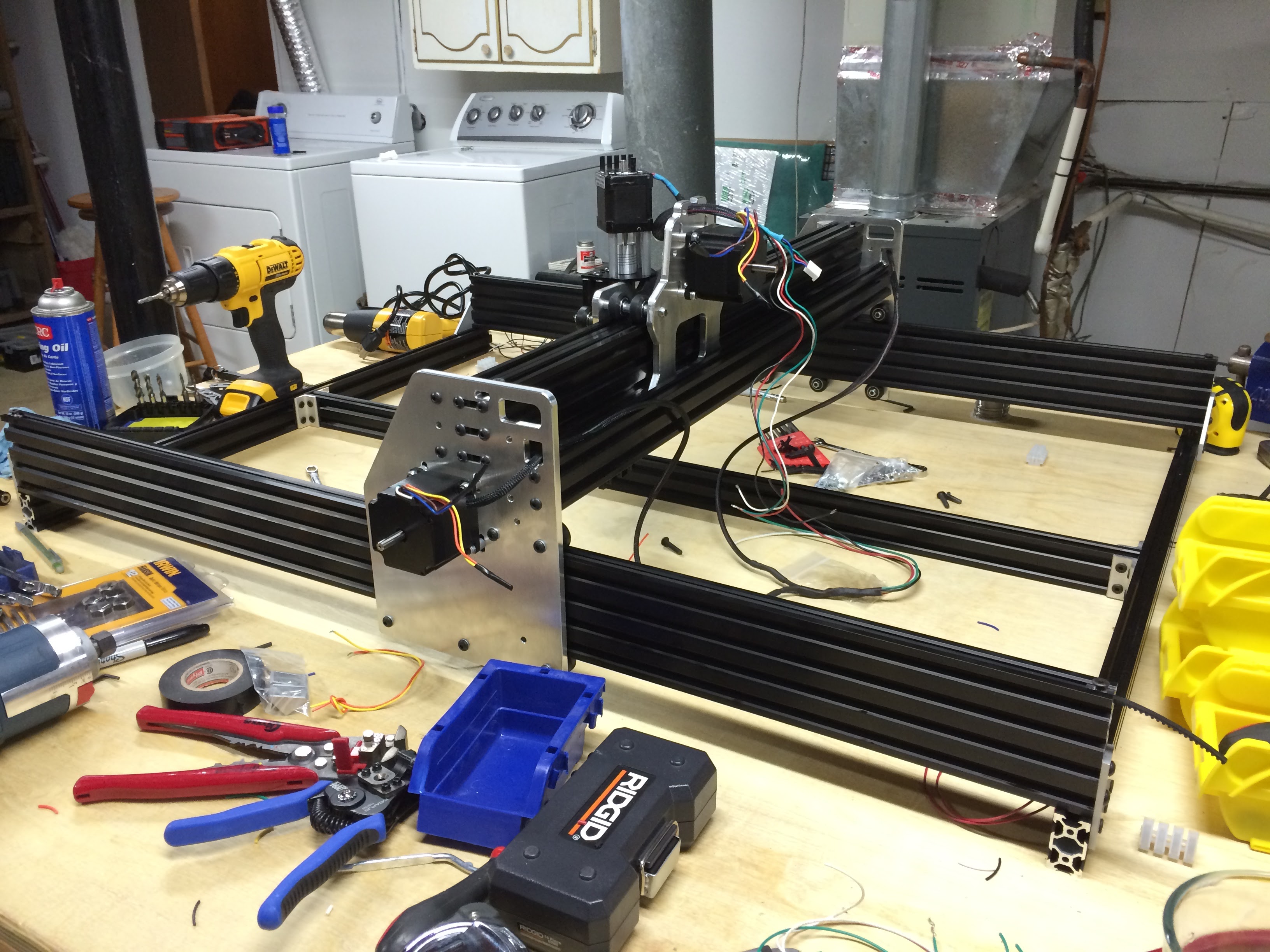

Rather than buying a complete kit, I mixed purchased components with DIY parts. I bought the V-slot extrusion, OpenBuilds gantry plates, V-wheels, timing belts, and NEMA 23 stepper motors. My Mendel 3D printer produced motor mount brackets, dust shields, wire management clips, and tool mounting adapters. I hand-assembled the electronics - custom stepper driver boards based on TB6560 chips, a parallel port breakout board, and power supply circuits.

This saved significant money while maintaining quality where it mattered. The 3D printed parts were another example of tools enabling better tools.

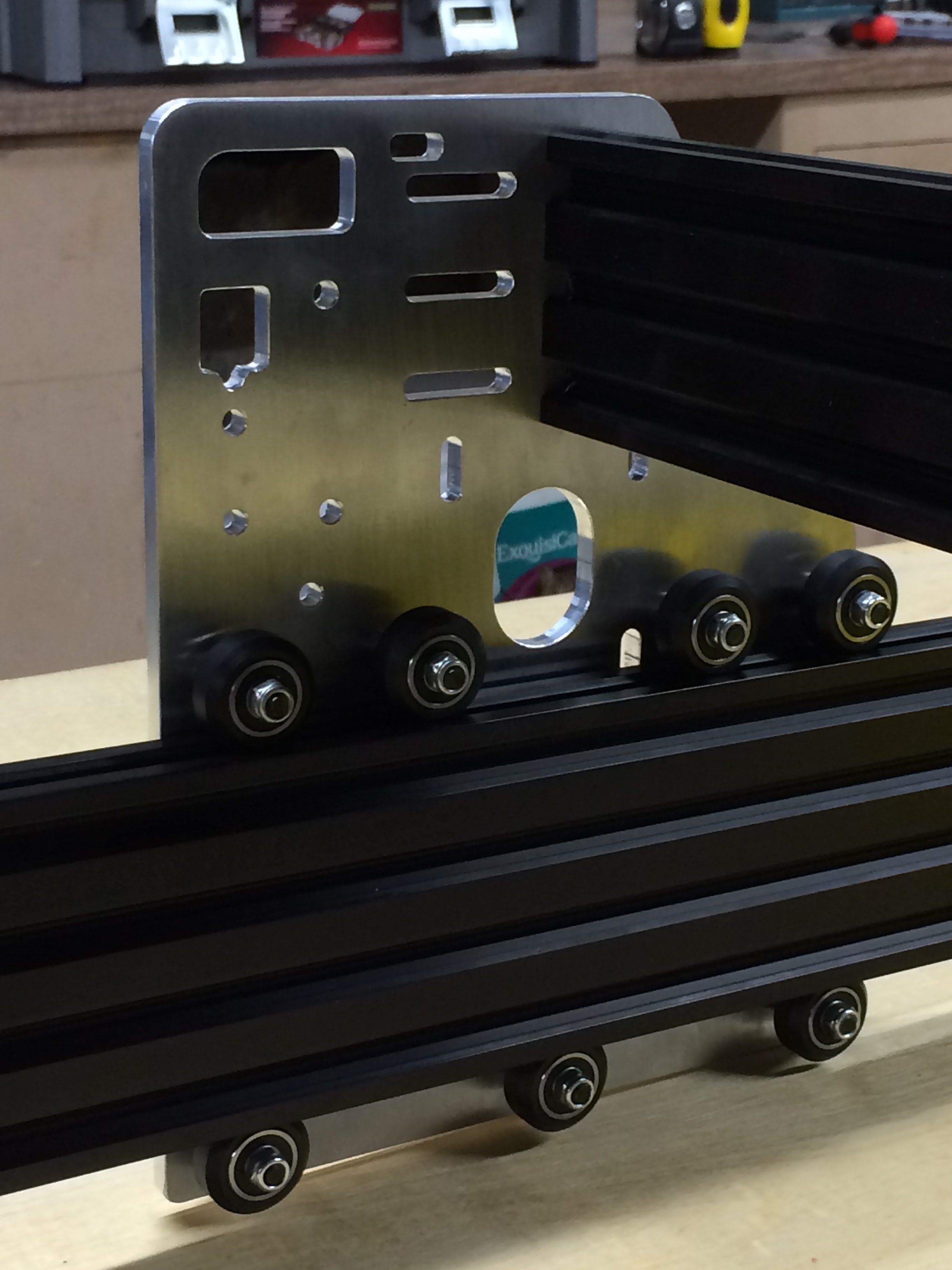

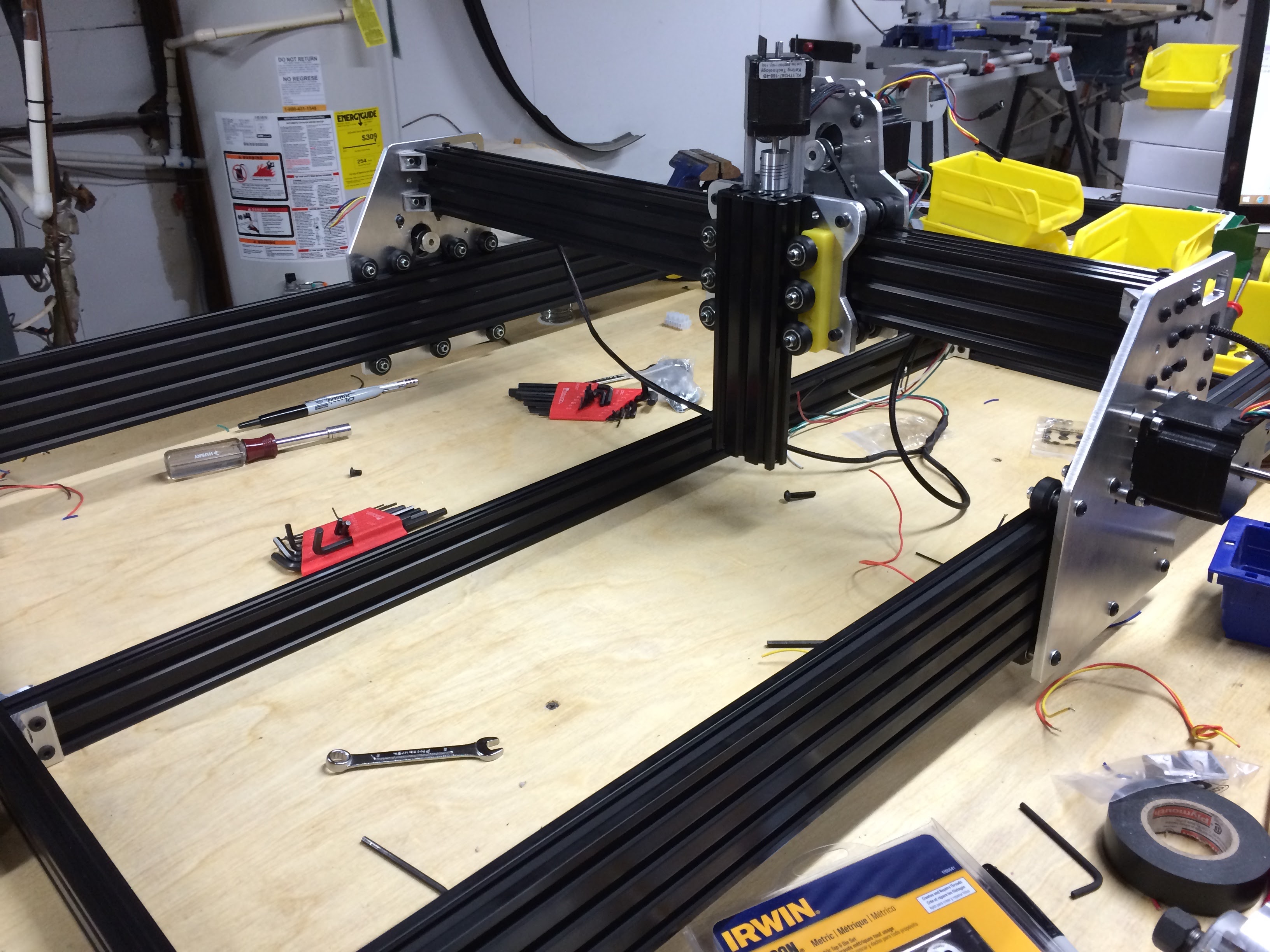

The V-slot system made assembly surprisingly straightforward. The base frame connected long extrusions with corner brackets. Gantry plates rode on V-wheels along the X-axis extrusion. A shorter extrusion spanned between gantry plates for the Y-axis beam. The Z-axis carriage rode on linear rails for the spindle mount.

The beauty of V-slot was its self-aligning nature. Once the extrusions were square, the V-wheels naturally tracked straight, eliminating the painstaking alignment I’d struggled with on separate linear rails.

The V-wheels used eccentric spacers to adjust tension against the V-slot. This took some learning - too tight and the motors strained, too loose and the carriage wobbled. The sweet spot was firm contact with smooth motion. GT2 timing belts needed proper tensioning too. I used the “guitar string” method: pluck the belt and listen for a clear tone.

Unlike 3D printers where a few millimeters of skew just affects aesthetics, CNC mills require precision squareness. I spent hours with a machinist’s square and dial indicator verifying both X and Y axes were perpendicular and parallel to the bed surface.

The electronics represented my first experience with TB6560 stepper drivers - a significant upgrade from RepRap electronics. These drivers could handle NEMA 23 motors at 3A per phase. I hand-assembled the boards, soldering the TB6560 chips, adding heatsinks and cooling fans, wiring optoisolators, and testing each driver independently.

This hands-on approach taught me stepper driver theory in detail - current limiting, microstepping, decay modes. Knowledge that proved invaluable for troubleshooting later.

I used a parallel port breakout board for control. This was “old school” even in 2014, but it was bulletproof reliable. No USB disconnects, no driver issues, just solid real-time control with Mach3 software.

The first real project was milling aluminum plates for a 3D printer build - a perfect test of the OX’s capabilities. These plates required precise hole locations within 0.1mm, flat surfaces for mounting, tapped holes for assembly, and clean edges without burrs.

I used a DeWalt 611 router with a 1/4" two-flute end mill at conservative settings: 12,000 RPM, 400mm/min feed rate, 0.5mm depth per pass, and WD-40 flood cooling. The results were excellent. Hole positions were accurate, surfaces were flat and square, and the aluminum finish was clean. This single project validated the entire build - the OX could do real work.

The software workflow felt like a huge leap from manually written G-code on the McWire. I designed parts in SolidWorks, used CamBam to generate toolpaths with proper ramping and lead-in/lead-out moves, then ran Mach3 to interpret G-code and control motion with tool offset management and work coordinate systems.

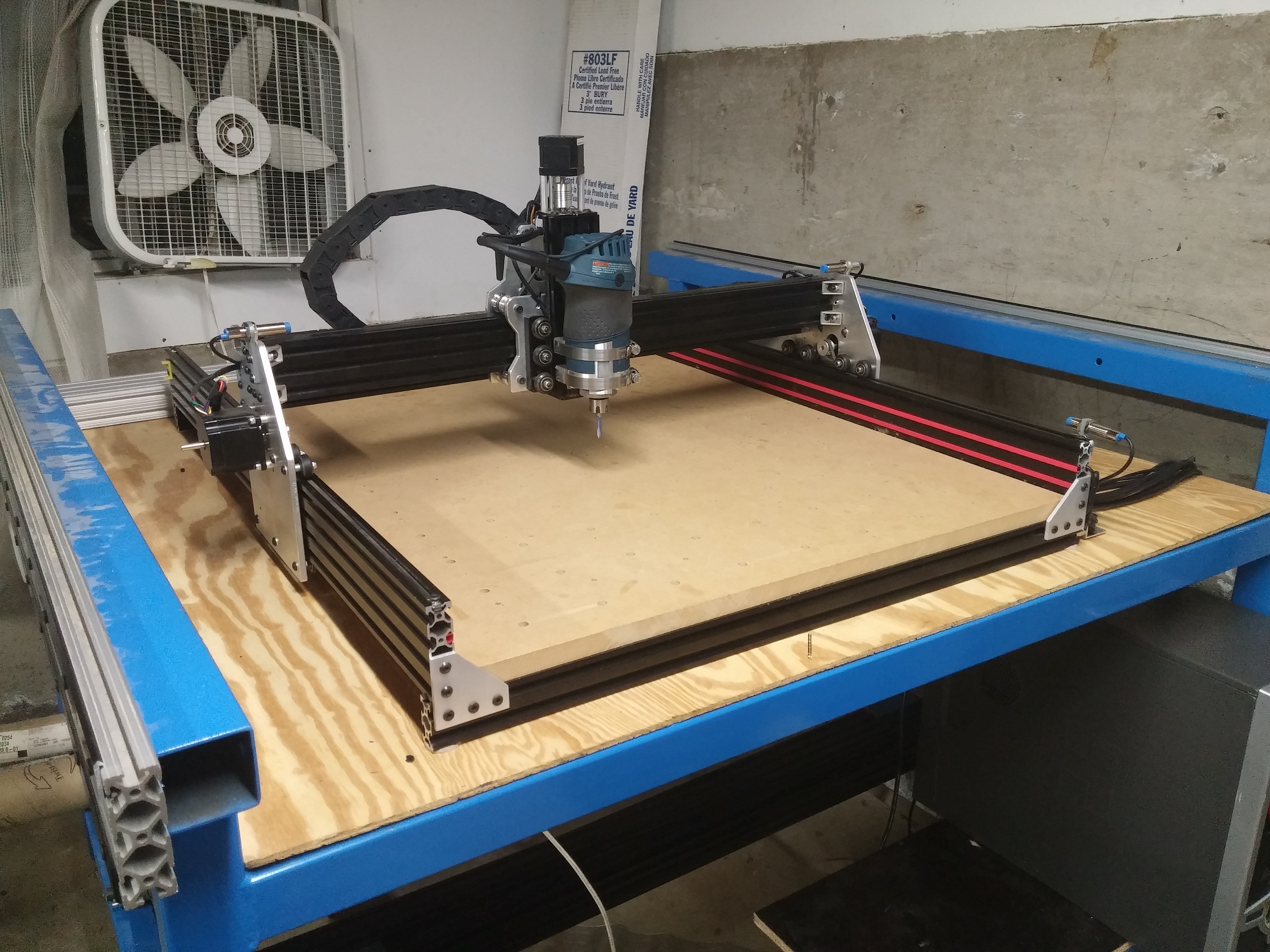

The OX handled aluminum well with its 750mm × 750mm working area and positioning accuracy within 0.05mm. I successfully milled 6061 and 7075 aluminum up to 6mm thick, plus wood, plastics, PCBs, and carbon fiber. You could tell it wasn’t designed for heavy steel work - the V-slot system flexed under very heavy cuts. But for aluminum and lighter materials, it was perfect.

Early on, I pushed speeds too high and got chatter, surface finish problems, and occasional stepper skips. Slowing down and taking heavier cuts at lower feed rates produced better results. The machine’s rigidity limited performance, not the electronics or motors.

Aluminum milling generates serious heat. Flood cooling with WD-40 made a dramatic difference in tool life and surface finish. I tried dry cutting once - the end mill dulled in minutes.

Having both 3D printing and CNC capabilities made the workshop far more capable. The 3D printer made custom mounts and fixtures for the CNC. The CNC milled precise aluminum parts for improved 3D printer components. Each machine enabled improvements to the other, mirroring the RepRap philosophy of tools creating better tools.

The OX served as my primary CNC for several years, milling hundreds of parts: aluminum plates for 3D printer upgrades, PCBs for electronics projects, wood signs, jigs and fixtures, and replacement parts for itself - aluminum motor mounts eventually replaced the 3D printed ones. The V-slot system held up well, with V-wheels wearing about every 100 hours of cutting time. Expected maintenance. The aluminum extrusion never wore measurably.

One unexpected benefit was joining the OpenBuilds community. The ecosystem of compatible parts, shared designs, and collaborative troubleshooting accelerated development significantly. When I needed a better Z-axis, the community had already designed, tested, and refined solutions. This echoed the RepRap experience - open source hardware thrives on shared knowledge and iterative improvement.

Editor’s Note (2025): The OpenBuilds OX design remains popular for DIY CNC builders. V-slot extrusion has become a standard building block for countless CNC and 3D printer designs. Modern builds often use linear rails on all axes for improved rigidity, and controller technology has moved from parallel port to grblHAL on 32-bit processors. But the fundamental OX design - simple, scalable, and effective - continues to be a solid starting point for anyone entering CNC machining. The hybrid approach of commercial + DIY components remains the smart way to build capable machines on a budget.