After years of development on the McWire RepStrap, I finally achieved the holy grail of the RepRap project: true self-replication. The McWire printed all the parts for a RepRap Mendel v2, which then printed an improved set of parts for a Mendel v3. This cascading upgrade path represents exactly what the RepRap community envisioned, with each generation of printer improving upon the last.

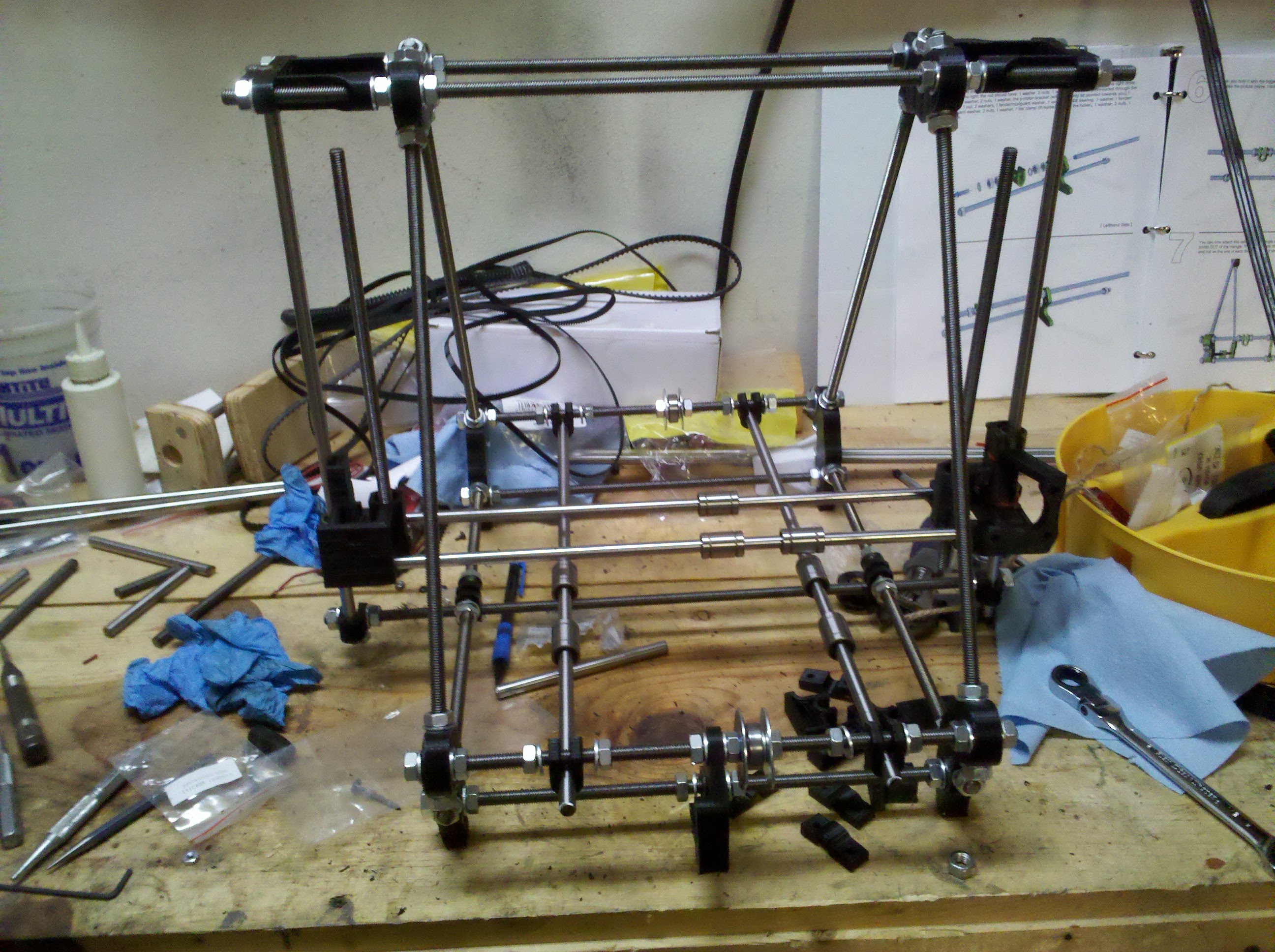

The journey began with the McWire, my wire-frame cartesian RepStrap built from threaded rod, lumber, and determination. Despite its crude appearance and 1mm nozzle, it was capable enough to produce functional plastic parts. The challenge was printing an entire set of RepRap Mendel components, which required dozens of hours of print time and careful calibration.

The McWire’s 1mm nozzle was far from ideal for detailed work. Print quality was chunky, layer adhesion required careful tuning, and bridging was nearly impossible. But for structural components like the Mendel’s frame vertices, motor mounts, and carriage parts, it was sufficient. I printed each part slowly, monitoring temperatures and making adjustments as needed. The large nozzle meant fast material deposition but poor detail resolution. Some parts required cleanup with files and drill bits to achieve proper fitment.

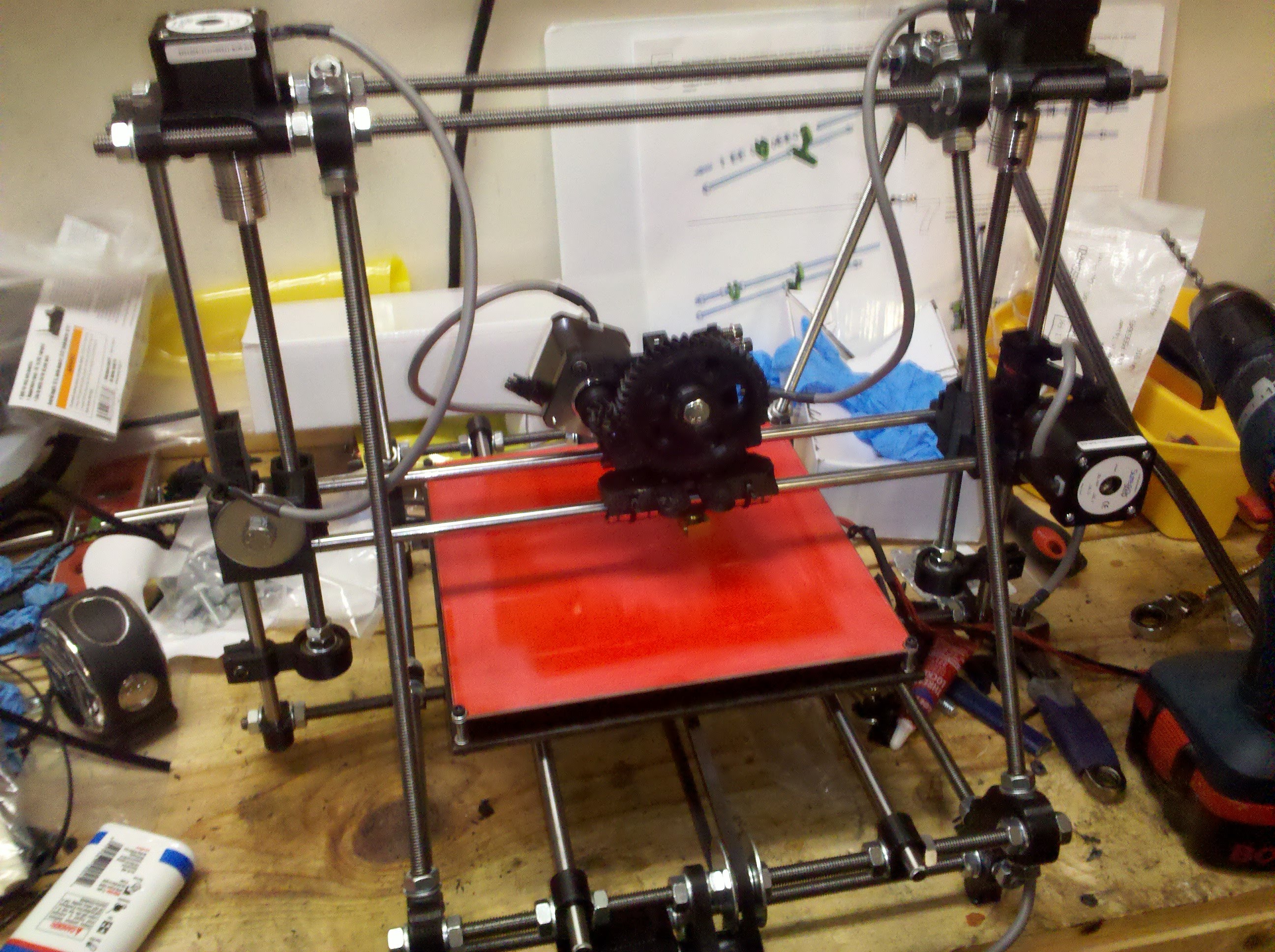

Early footage of the Mendel v2 in operation, printed entirely by the McWire

With all the plastic parts printed, I assembled the Mendel v2. The design was elegant compared to the McWire, featuring a triangular frame for rigidity, linear bearings on smooth rods instead of threaded rod, and a proper heated bed. But most importantly, I upgraded to a 0.6mm nozzle.

The difference was immediate. Print quality jumped dramatically with the smaller nozzle. Details were crisper, overhangs were manageable, and dimensional accuracy improved significantly. The Mendel could print parts that the McWire simply couldn’t produce. With the v2 operational and printing reliably, I started printing an improved set of parts for a third-generation Mendel. The community had been iterating on the design, fixing issues and optimizing structural components. The v2’s 0.6mm nozzle made this practical, and each part came off the bed cleaner and more accurate than anything the McWire had produced.

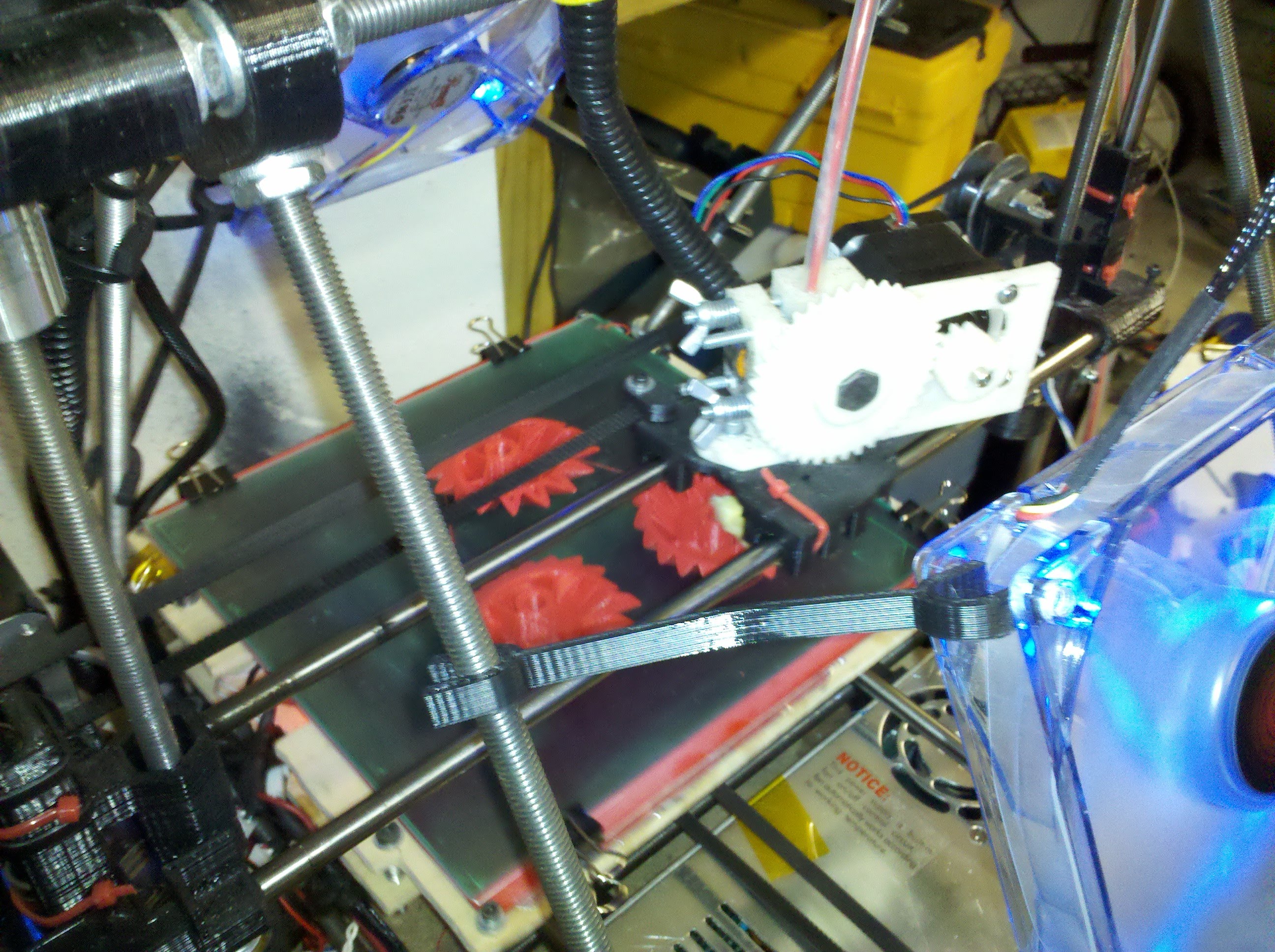

The biggest upgrade for the Mendel v3 was the J-Head hotend, which I co-developed with Brian Reifsnyder. This design featured a 0.4mm nozzle, the finest resolution I’d achieved yet. The J-Head used a single machined aluminum piece with a distinct cold zone and hot zone, reducing heat creep that could soften filament too early. The tighter tolerances meant cleaner retractions and better bridging. Brian handled the precision machining while I focused on testing and iteration. We went through several prototypes, adjusting dimensions and testing different nozzle geometries until we had something that worked reliably.

The jump to 0.4mm opened up new possibilities. Fine text became readable, detailed mechanical parts had proper clearances, and surface finish improved dramatically. What had been impossible with the McWire’s 1mm nozzle was now routine.

The Mendel v3 with J-Head hotend printing high-quality parts

You don’t need a perfect printer to build a better printer. The McWire was crude, but it was good enough to bootstrap to something better. It couldn’t have printed J-Head mount parts directly because they required tolerances it couldn’t achieve. But it could print parts for the Mendel v2, which could then print parts for the Mendel v3.

Having a working printer accelerates development. Instead of ordering parts or borrowing machine time, I could iterate designs overnight. The J-Head collaboration with Brian worked because I could test prototypes immediately and he could ship improved versions the next day.

The McWire was expensive in time and frustration. The Mendel v2 was easier because the McWire existed. The Mendel v3 was easier still because the v2 existed. Anyone with a Mendel v3 could print parts for someone else’s first printer.

Editor’s Note (2025): The RepRap Mendel design has been superseded by numerous improved designs such as the Prusa i3, Voron, and countless others. But the self-replication methodology pioneered with these early machines remains fundamental to the open-source 3D printing movement. Modern printer farms often trace their lineage back to a single bootstrapped machine, just like this Mendel v3 traces back to the original McWire. The J-Head hotend design influenced countless later hotends, and Brian Reifsnyder’s contribution to the community extended far beyond this single collaboration.