Building a Large Custom Dual-Extruder 3D Printer

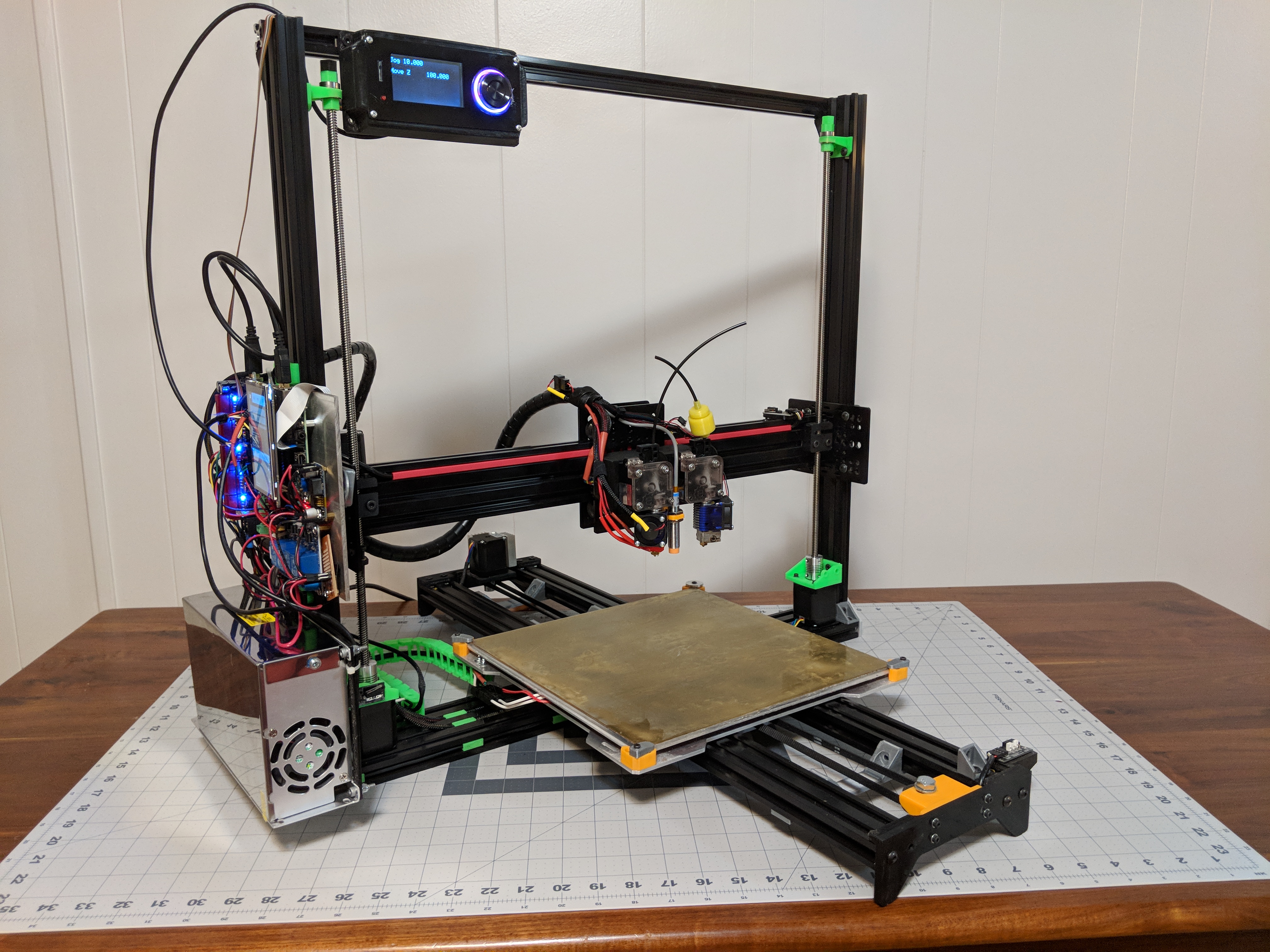

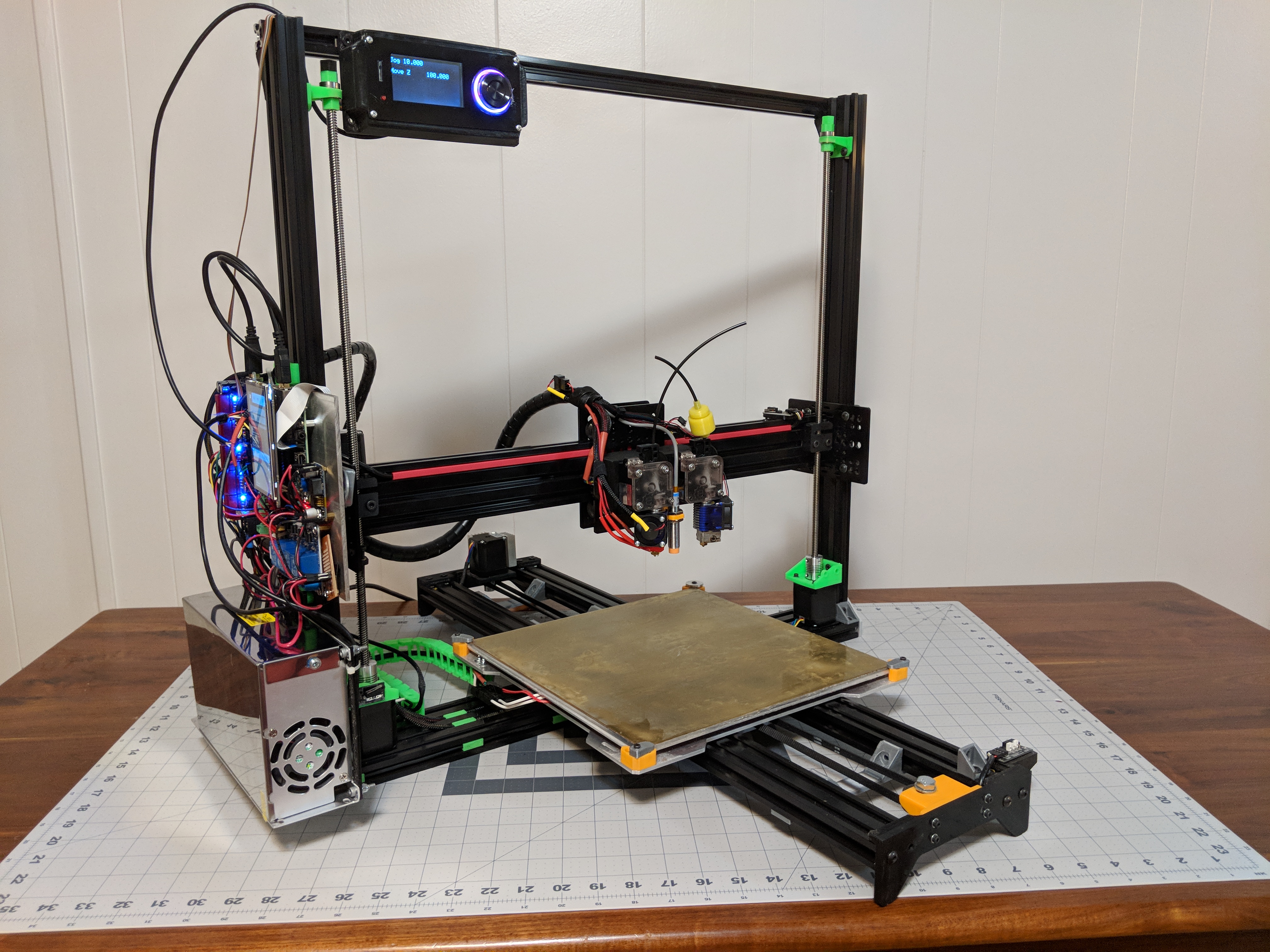

Building a large-format dual-extruder printer with V-slot aluminum frame and multi-material capabilities

Building a large-format dual-extruder printer with V-slot aluminum frame and multi-material capabilities

Achieving the RepRap vision: the McWire printed a Mendel, which printed better Mendels, implementing true self-replication

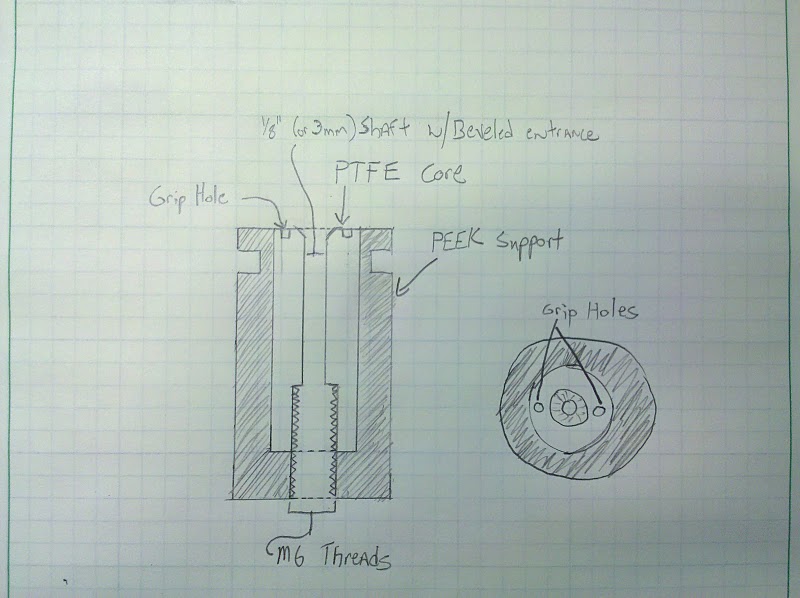

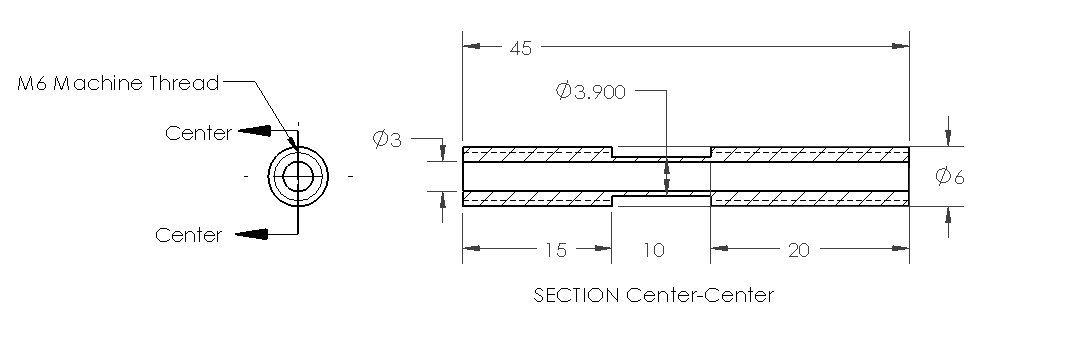

A collaboration between electronics expertise and precision machining that created the J-Head, one of the most influential hot-end designs in RepRap history

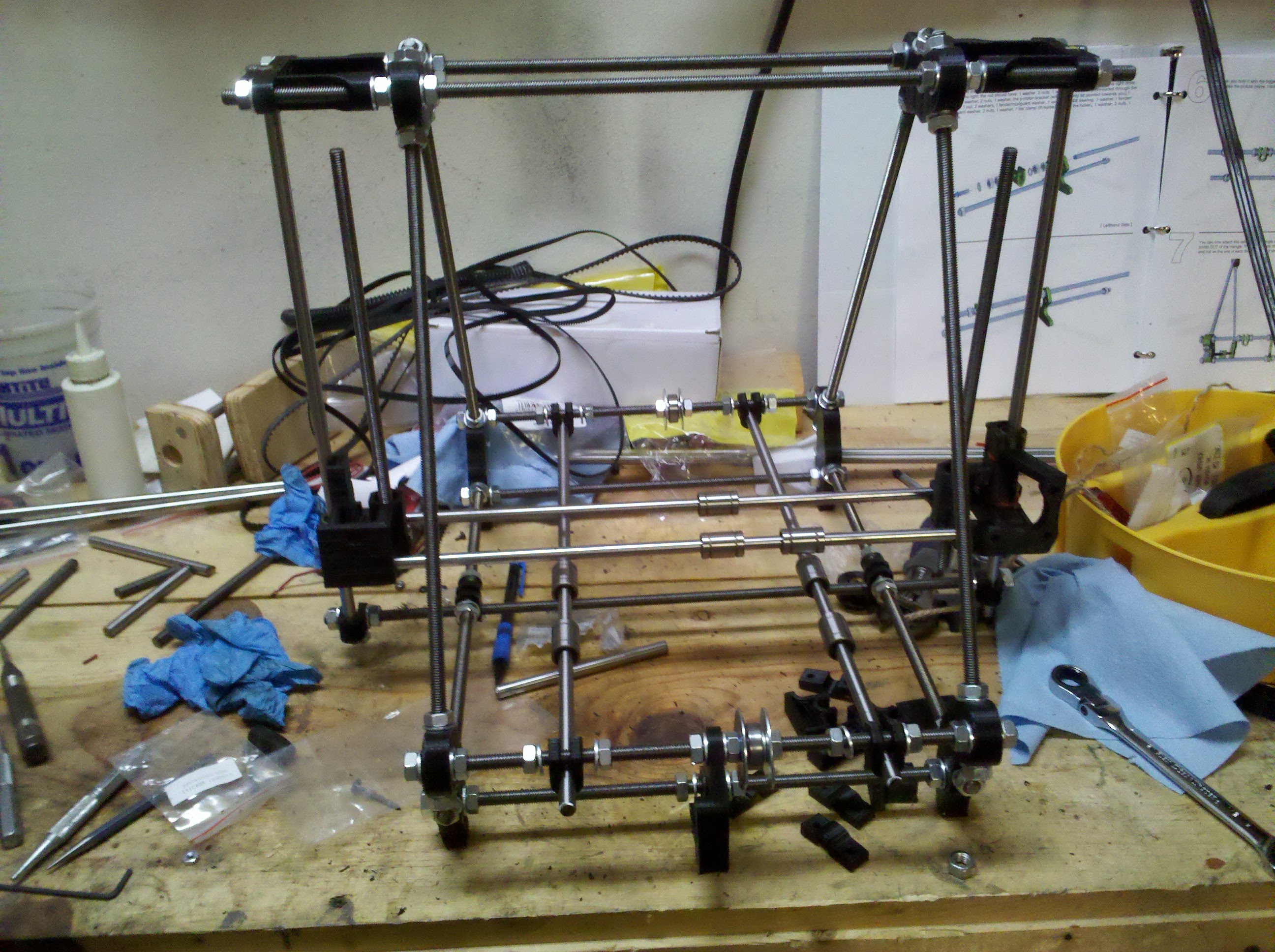

Printing Mendel parts on the McWire and assembling a self-replicating printer capable of printing its own replacement components

Systematic troubleshooting solutions for extruder jams, flow issues, temperature problems, and mechanical alignment

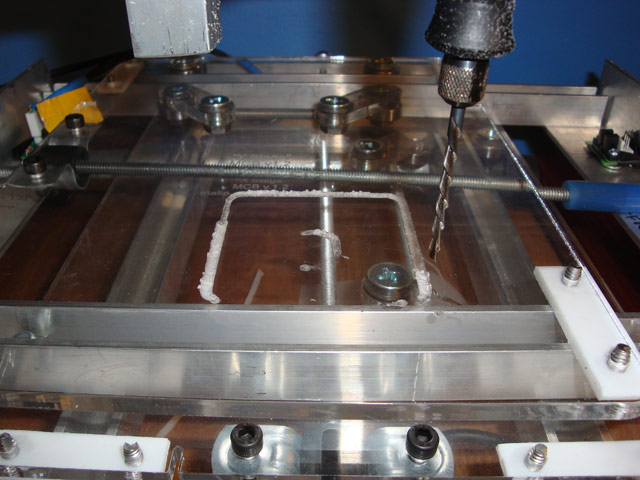

Converting the McWire 3D printer into a CNC mill with a Dremel toolhead—the beginning of workshop tool progression

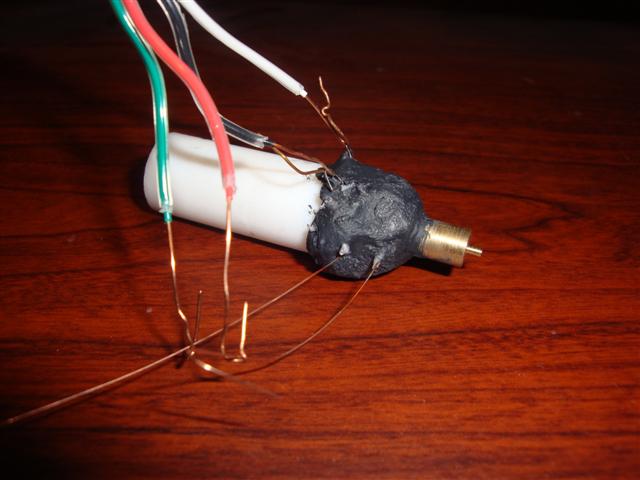

Two years of extruder experimentation: from nichrome wire failures to reliable resistor-based hotends

Building a 3D printer from threaded rod, lumber, and determination—the first step in the RepRap self-replication journey